Plastic Crusher Machines

BSC Lines

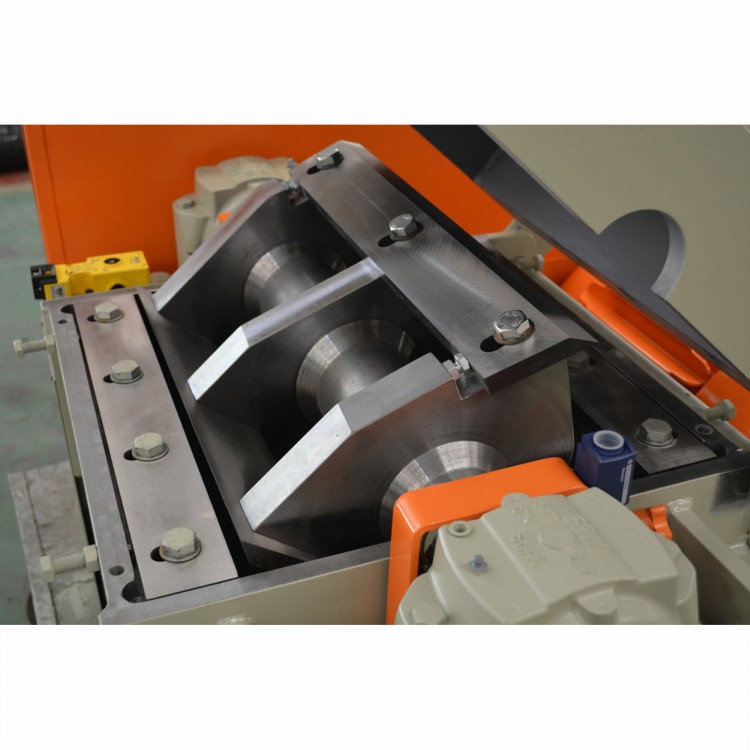

The plastics crushers from the BSC crusher line are high-rotation and their main characteristics are high productivity, low cost and ease of operation and maintenance.

This plastic recycling crusher serves the grinding of the most varied types and sizes of plastic materials, from grinding small parts to large pieces. This machine can be used in production lines or grinding centres, with or without the use of water. With nozzles and grinding chambers ranging from 200mm to 1000mm, it meets a wide spectrum of needs.

As a difference, the plastic crushers in the BSC line feature spaced bearing seats, with insulation to block the entry of water into the bearings, preventing them from being affected by dirt and humidity, providing longer life to the bearings.

The BSC line has plastic crushers with exceptional ease of maintenance, as it has self-aligning bearings fixed by clamping bushes, which facilitate replacement. The quick change of the sieve, sitting on the grinding box, is also characteristic of this line of plastic crusher, which in addition to facilitating the change of the sieve also provides greater robustness necessary for grinding.

In terms of safety, this plastic grinding machine is very well designed. In addition to having a rotor brake monitored by micro limit stroke, ensuring operator safety when changing knives and other maintenance and cleaning of the equipment, it also has a safety solenoid switch with certified lock, fixed next to the side of the feed nozzle of the machine.

Some features of this crusher that guarantee excellent value for money.

- High grinding yield.

- Rotor with knives positioned in a “scissor” cut, with six offset cutting points*, providing a lower peak energy consumption.

- Knives made from special O1 steel.

- Adjustable fixed and rotor knives.

- Bearings away from the grinding box.

- Easy maintenance crusher.

- Dry or water grinding.

- Quick change of the sieve, done from above.

- Safety key with lock next to the feed nozzle.

- Compliance with current Safety Standards and specific standard ABNT NBR 15.107.

*From 600mm chamber width.