PET Recycling Systems

PET Recycling Systems

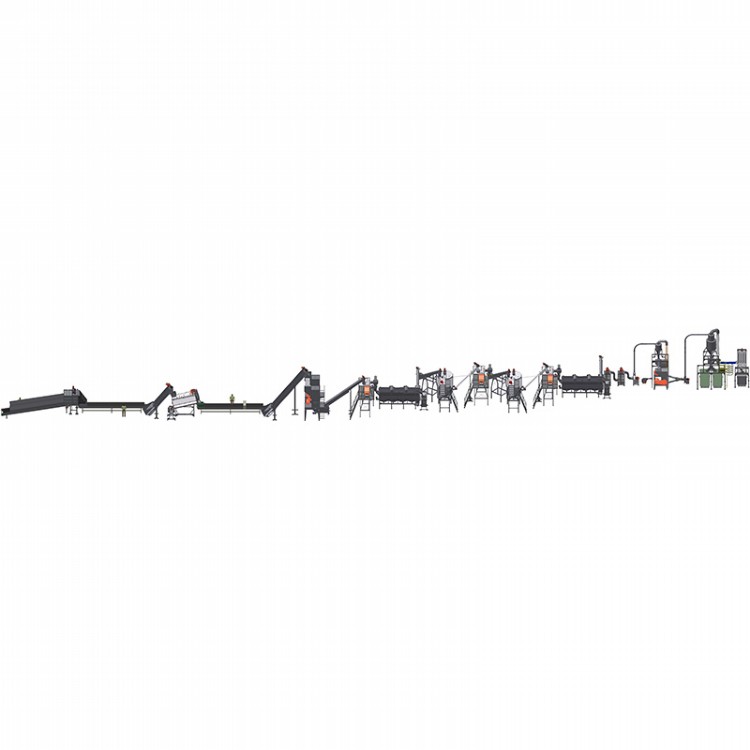

Cold wash

The complete system for PET recycling with cold washing comprises the steps of removing and separating labels and caps, grinding, washing and drying, providing a high quality flake (milled material). The configuration is customized according to the specific need of each customer because Seibt systems are modular and the individual equipment allows adding, removing or changing the order of a piece of equipment, adjusting the system to the customer's need. Production capacities from 500 to 2000 Kg/h or special systems.

Hot wash

The complete system for PET recycling with hot washing comprises the steps of removing and separating labels and caps, grinding, hot washing – super washing - and drying, providing a high quality decontaminated flake (milled material) with the necessary conditions of a food grade recycled and its use in bottle-to-bottle technology. Production capacities from 500 to 2000 Kg / h or special projects.

Individual Equipment

SEIBT equipment can be supplied individually or in sets to work with other equipment meeting specifics needs of each customer.

The individual equipment includes, in addition to the entire line of mills, shredder, extruders, pelletizers, agglutinators, PET Recycling Systems, PE and PP: conveyors belts, conveyors screws, label extractor, tanks, reactors, pre-dryers, dryers, exhaust fans and silos.

Also check out:

SEIBT BSC mill (new line)

SEIBT A2 mill (new line)

Production capacity

| Up to 500 kg/h |

| Up to 1000 kg/h |

| Up to 1500 kg/h |

| Up to 2000 kg/h |

| Up to 2500 kg/h |

| Up to 3000 kg/h |