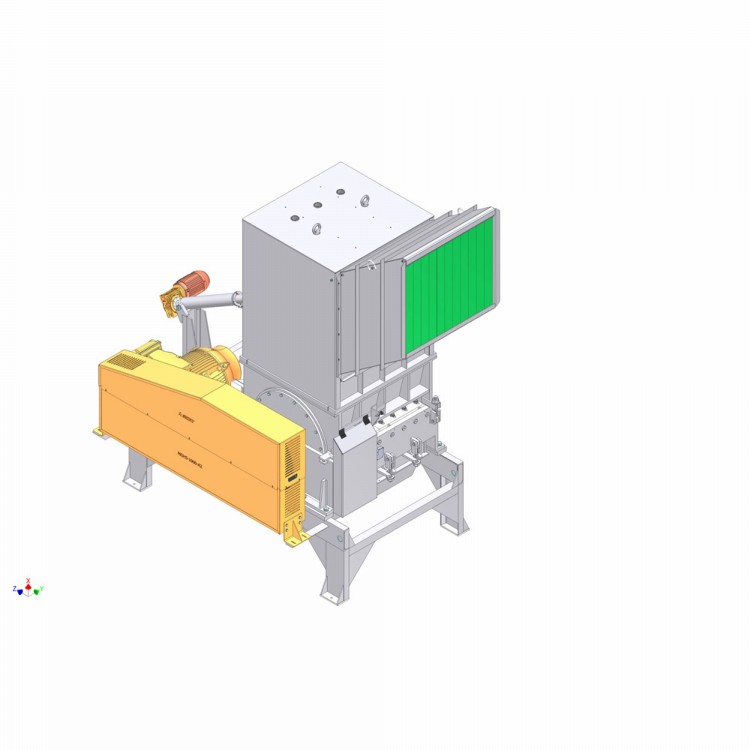

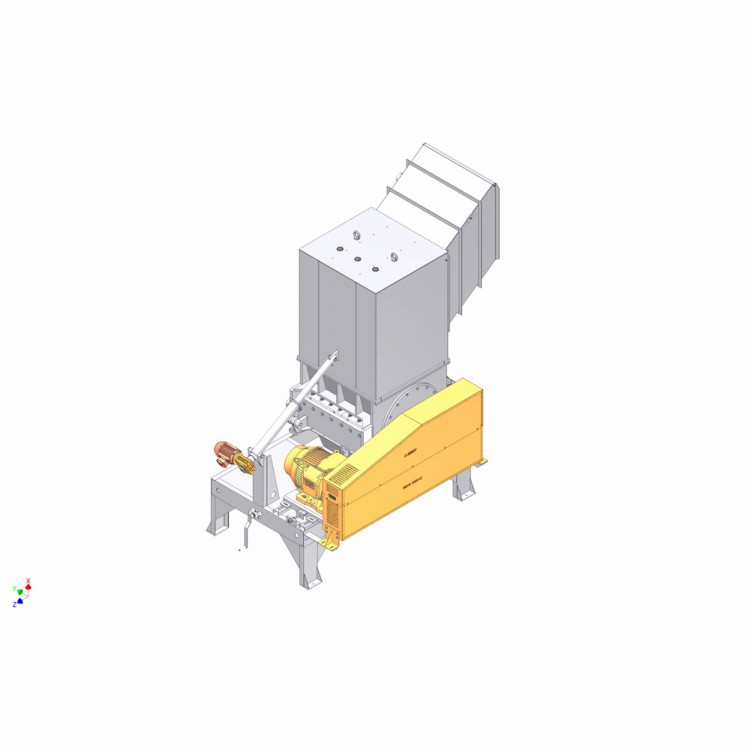

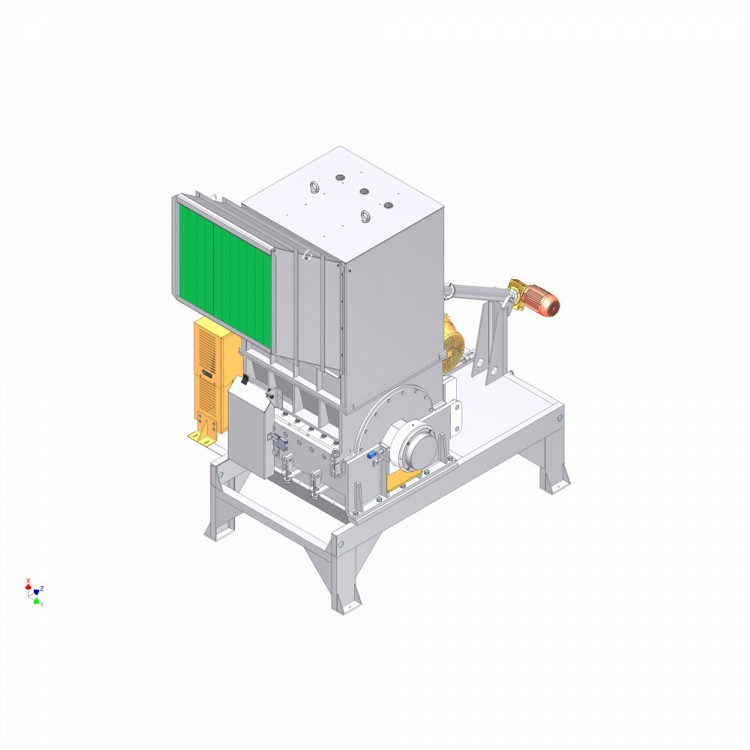

Plastic Crusher Machines

A2 Lines

The new line of A2 mills has as main differences a high productivity, robustness, practicality in operation and safety.

Indicated for grinding or recycling plants with or without use of water due to the large productive capacity and differentiators such as rotor with inserts; template for quick knives' change; magazine for industrial screen and articulated nozzle.

Its size meets the grinding of large volume pieces of most varied types of plastic materials; heavy grinding such as lees or grinding of small parts that require a large production.

- High grinding performance.

- Rotor with side discs; razors positioned in a "scissor" cut, with six cut-off points *.

- Rotor with inserts *.

- Grinding box with inserts for placing fixed knives*.

- Knives made of special O1 steel.

- Device/template for adjusting its knives outside the mill.

- Dry or wet grinding.

- Modern design that facilitates maintenance - switching knives and industrial screen.

- Security key with lock next to the front cover for access to the grinding chamber.

- Compliance with the current Safety Norms and specific Norm ABNT NBR 15.107.

* For mills with a 500mm chamber width upwards.